Hello from CEDIA 2021 in Indianapolis! It’s just the first hour of the show and we are already having great conversations with new faces as well as old friends. If you are in town for the show this week, be sure to come by and say hello.

Meanwhile, here is what is going on in Jetbuilt:

Item Lead Times

No one is more aware of the current issue with product fulfillment than the AV Integrator. But long before Covid many projects would be sold using equipment that had lengthy backorders.

To help with this, Jetbuilt has implemented a “Lead Time” indicator. This will give you a sense of availability for the items you are using in your projects.

We launched this feature with an initial batch of manufacturers feeding the data. Each week more vendors are beginning to include Lead Times with their updates.

Stock Module

This week at the show we are previewing our new Stock Module.

Stock launches September 15, when we will activate a free evaluation for all Jetbuilt users.

In the meantime, here is a bit of a visual tour of the core functionality:

Show Stock in Builder

Stock will track your actual warehouse inventory of items large and small. You begin to see the value of Stock right in the Jetbuilt Builder. As you populate your project with items, we will indicate those that you have on-hand. This feature can be turned on or off in company settings.

For larger organizations, you can choose to view items in your particular office location, just your country, or all your locations around the world.

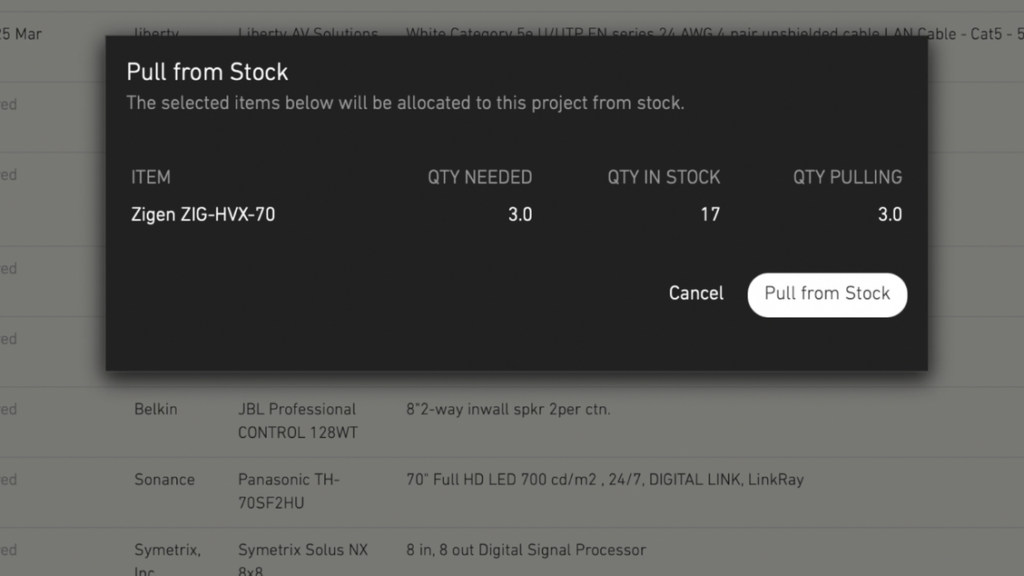

Pull From Stock in Purchasing

When creating your POs in the purchasing area we will again indicate how many items you have on-hand of everything in the project. You can opt to pull from stock to fulfill your project.

Additionally, you can now order more than your project requires – perhaps to achieve discounts, or simply to replenish your typical inventory.

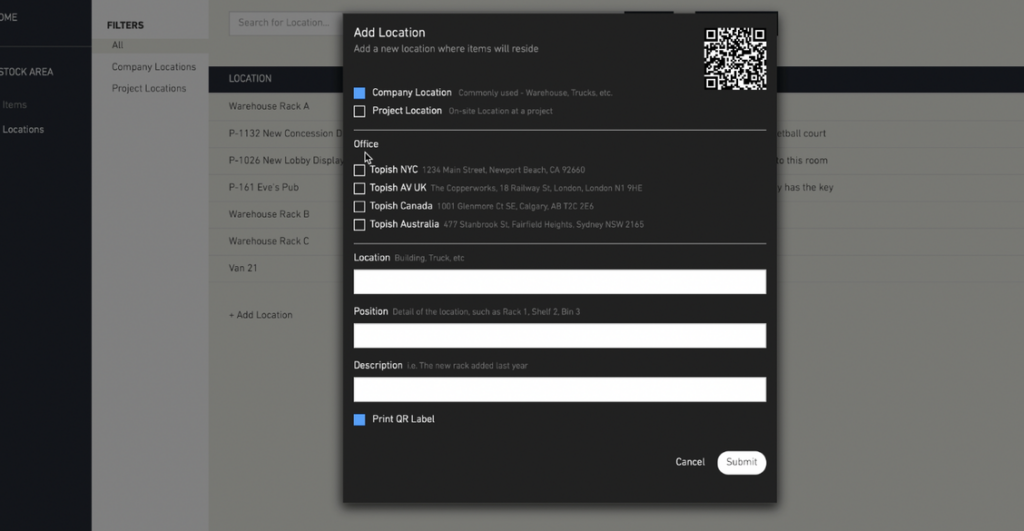

Create Stock Locations

You can create a host of locations for your items. These can be as granular as you like, such as which warehouse, rack, row, and shelf.

You can also make locations from trucks and vans, as well as temporary storage areas onsite at your active projects.

Receive Items into Warehouse

As orders arrive, the team scans a storage location and records all serial numbers of primary items.

They then print and attach QR codes to the outer boxes and optionally affix laminated labels with small codes to the back of the devices themselves.

Move Items

As Technicians move items from the warehouse, to their van, then to the job site, they simply scan with their phone to make each move.

These codes can be scanned during future service calls which will open the item in Jetbuilt’s Assets area along with warranty, login, and other information.

Thank you again for using Jetbuilt,

Paul and the Jetbuilt team